|

|

|

Subset delivers Ships high performance NDAA components accelerating autonomy, unmanned systems, and robotics development.

| Batteries | Motors | Sensors | Boards |

|---|---|---|---|

| 1500 mAh | 250 KV | LWIR | Sensor |

| 1000 mAh | 1000 KV | RGB | Compute |

| 15000 mAh | 2500 KV | IMU | Controller |

| LiPo / LiOn | 1-20 NM | SW + Docs | SWaP + SW |

| Text or Email your requirements. Join the mailing list. Get started now. |

Pro Capability, Everyday Availability

| Built for autonomy, unmanned systems & robotics | Designed for NDAA compliance | Engineered for performance |

Accelerate Development, Increase Capability

Engineers

Develop fast.

| Text or Email your requirements. Get started now. |

Supply Chain

Procure fast.

| Text or Email your requirements. Get started now. |

Hobbyists

Hack fast.

| Text or Email your requirements. Get started now. |

Students

Learn Fast.

| Text or Email your requirements. Get started now. |

Industry

Deliver fast.

| Text or Email your requirements. Get started now. |

Government

Secure fast.

| Text or Email your requirements. Get started now. |

Batteries

LiPo - Lithium Polymer

A lithium polymer battery, or more correctly, lithium-ion polymer battery (abbreviated as LiPo, LIP, Li-poly, lithium-poly, and others), is a rechargeable battery derived from lithium-ion and lithium-metal battery technology. The primary difference is that instead of using a liquid lithium salt (such as lithium hexafluorophosphate, LiPF6) held in an organic solvent (such as EC/DMC/DEC) as the electrolyte, the battery uses a solid (or semi-solid) polymer electrolyte such as polyethylene glycol (PEG), polyacrylonitrile (PAN), poly(methyl methacrylate) (PMMA) or poly(vinylidene fluoride) (PVdF). Other terms used in the literature for this system include hybrid polymer electrolyte (HPE), where “hybrid” denotes the combination of the polymer matrix, the liquid solvent, and the salt.

Polymer electrolytes can be divided into two large categories: dry solid polymer electrolytes (SPE) and gel polymer electrolytes (GPE).

In comparison to liquid electrolytes and solid organic electrolytes, polymer electrolytes offer advantages such as increased resistance to variations in the volume of the electrodes throughout the charge and discharge processes, improved safety features, excellent flexibility, and processability. These batteries provide higher specific energy than other lithium battery types.

They are used in applications where weight is critical, such as laptop computers, tablets, smartphones, radio-controlled aircraft, and some electric vehicles.

Like other lithium-ion cells, LiPos operate based on the intercalation and de-intercalation of lithium ions between a positive and a negative electrode. However, instead of a liquid electrolyte, LiPos typically use a gelled or solid polymer-based electrolyte as the conductive medium. A microporous polymer separator is used to prevent direct contact between the electrodes, while still allowing lithium-ion transport.

A typical cell has four main components: a positive electrode, a negative electrode, a separator, and an electrolyte. The separator itself may be a polymer, such as a microporous film of polyethylene (PE) or polypropylene (PP); thus, even when the cell has a liquid electrolyte, it will still contain a “polymer” component. In addition to this, the positive electrode can be further divided into three parts: the lithium-transition-metal-oxide (such as LiCoO2 or LiMn2O4), a conductive additive, and a polymer binder of poly(vinylidene fluoride) (PVdF). The negative electrode material may have the same three parts, only with carbon replacing the lithium-metal-oxide. The main difference between lithium-ion polymer cells and lithium-ion cells is the physical phase of the electrolyte, such that LiPo cells use dry solid, gel-like electrolytes, whereas Li-ion cells use liquid electrolytes.

LiOn - Lithium Ion

Common Cell Sizes

| Type | D mm | L mm | Note |

|---|---|---|---|

| 18650 | 18 | 65 | Widely Adopted LiOn |

| 21700 | 21 | 70 | Next Gen LiOn |

| 26700 | 26 | 70 | LiFePO4 |

Common Pack Congurations

1S1P

3S1P

6S1P

| Text or Email your requirements. Get started now. |

Motors

BLDC - Brushless Direct Current

A brushless DC electric motor (BLDC), also known as an electronically commutated motor, is a synchronous motor using a direct current (DC) electric power supply. It uses an electronic controller to switch DC currents to the motor windings, producing magnetic fields that effectively rotate in space and which the permanent magnet rotor follows. The controller adjusts the phase and amplitude of the current pulses that control the speed and torque of the motor. It is an improvement on the mechanical commutator (brushes) used in many conventional electric motors.

Brushless motors fulfill many functions originally performed by brushed DC motors, but cost and control complexity prevents brushless motors from replacing brushed motors completely in the lowest-cost areas. Nevertheless, brushless motors have come to dominate many applications, particularly devices such as computer hard drives and CD/DVD players. Small cooling fans in electronic equipment are powered exclusively by brushless motors. They can be found in cordless power tools where the increased efficiency of the motor leads to longer periods of use before the battery needs to be charged. Low speed, low power brushless motors are used in direct-drive turntables for gramophone records. Brushless motors can also be found in marine applications, such as underwater thrusters. Drones also utilize brushless motors to elevate their performance.

The advantages of a brushless motor over brushed motors are high power-to-weight ratio, high speed, nearly instantaneous control of speed (rpm) and torque, high efficiency, and low maintenance. Brushless motors find applications in such places as computer peripherals (disk drives, printers), hand-held power tools, and vehicles ranging from model aircraft to automobiles. In modern washing machines, brushless DC motors have allowed replacement of rubber belts and gearboxes by a direct-drive design.

Common Motors

| Type | Note |

|---|---|

| Servo | Closed-loop |

| Stepper | Open-loop |

| BLDC | Brusheless Direct Current |

| PMSM | Permanent Magnet Syncronous Motor |

| Text or Email your requirements. Get started now. |

Sensors

Thermal Image Sensor Module

Robotic sensors are used to estimate a robot’s condition and environment. These signals are passed to a controller to enable appropriate behavior.

Sensors in robots are based on the functions of human sensory organs. Robots require extensive information about their environment in order to function effectively.

Classification Sensors provide analogs to human senses and can monitor other phenomena for which humans lack explicit sensors.

Simple Touch: Sensing an object’s presence or absence. Complex Touch: Sensing an object’s size, shape and/or hardness. Simple Force: Measuring force along a single axis. Complex Force: Measuring force along multiple axes. Simple Vision: Detecting edges, holes and corners. Complex Vision: Recognizing objects. Proximity: Non-contact detection of an object. Sensors can measure physical properties, such as the distance between objects, the presence of light and the frequency of sound. They can measure:

Object Proximity: The presence/absence of an object, bearing, color, distance between objects. Physical orientation. The co-ordinates of object in space. Heat: The wavelength of infrared or ultra violet rays, temperature, magnitude, direction. Chemicals: The presence, identity, and concentration of chemicals or reactants Sound: The presence, frequency, and intensity of sound. Motion controllers, potentiometers, tacho-generators and encoder are used as joint sensors, whereas strain-gauge based sensing is used at the end-effector location for contact force control.

Internal sensor* It is the part of the robot. Internal sensors measure the robot’s internal state. They are used to measure position, velocity and acceleration of the robot joint or end effectors.

Position sensor Position sensors measure the position of a joint (the degree to which the joint is extended). They include:

Encoder: a digital optical device that converts motion into a sequence of digital pulses. Potentiometer: a variable resistance device that expresses linear or angular displacements in terms of voltage. Linear variable differential transformer: a displacement transducer that provides high accuracy. It generates an AC signal whose magnitude is a function of the displacement of a moving core. Synchros and Resolvers Velocity Sensor A velocity or speed sensor measures consecutive position measurements at known intervals and computes the time rate of change in the position values.

Applications In a parts feeder, a vision sensor can eliminate the need for an alignment pallet. Vision-enabled insertion robots can precisely perform fitting and insertion operations of machine parts.

RGB Camera Sensor Module

Common Sensors

| Type | Description | Note |

|---|---|---|

| IMU | Inertial Measurement Unit | Accel, Gyro, Mag |

| RGB Camera | Visible Color | |

| IR Camera | Nightvision | |

| LWIR Camera | Thermal |

| Text or Email your requirements. Get started now. |

Boards

Controller Board

A single-board microcontroller is a microcontroller built onto a single printed circuit board. This board provides all of the circuitry necessary for a useful control task: a microprocessor, I/O circuits, a clock generator, RAM, stored program memory and any necessary support ICs. The intention is that the board is immediately useful to an application developer, without requiring them to spend time and effort to develop controller hardware.

As they are usually low-cost, and have an especially low capital cost for development, single-board microcontrollers have long been popular in education. They are also a popular means for developers to gain hands-on experience with a new processor family.

A microprocessor development board is a printed circuit board containing a microprocessor and the minimal support logic needed for an electronic engineer or any person who wants to become acquainted with the microprocessor on the board and to learn to program it. It also served users of the microprocessor as a method to prototype applications in products.

Unlike a general-purpose system such as a home computer, usually a development board contains little or no hardware dedicated to a user interface. It will have some provision to accept and run a user-supplied program, such as downloading a program through a serial port to flash memory, or some form of programmable memory in a socket in earlier systems.

Common Boards

| Type | Note | |

|---|---|---|

| Carrier Board | Hosts a board | |

| System on Module | Hosts a Processor | |

| SBC Single Board Computer | Complete Computer on a Board | |

| Sensor Board | Hosts sensors | |

| Motor Controller Board | Hosts motor control processor |

“Existing NDAA components fast follow, wrongly size features, or lack support. Non-NDAA options add untenable risk. We’re building components we wish we had from prototype to production.” - Substep team after designing and shipping systems in all domains.

| Text or Email your requirements. Get started now. |

Software

Substep provides open source code, and documentation.

Support

Substep provides full support.

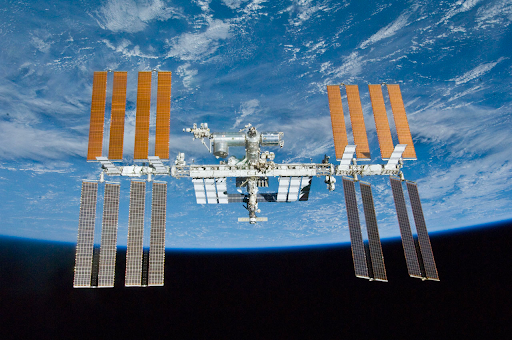

Systems

Substep supplies components for industrial robots, warehouse robots, mobile robots, robotic arms, quadrupeds, humanoids, space systems, satellites, aerospace, avionics, undersea robots, unmanned systems, uncrewered systems, drones, AMR, UAS, UAV, UUV, USV, cyber-physical systems and more.

| Type | Note |

|---|---|

| Drone | UAV, UAS, Unmanned Aerial Vehicle |

| UAV | Unmanned Aerial Vehicle |

| UAS | Unmanned Aerial System |

| USV | Unmanned Surface Vehicle |

| UUV | Unmanned Underwater Vehicle |

| AMR | Automoous Mobile Robot |

| Humanoid | 2 Legged Robot |

| Quadruped | 4 Legged Robot |

Pricing

We work with you on design, volume quantity, and pricing from single samples to millions of unit mass production units.

| Text or Email your requirements. Get started now. |

About

Substep is for engineers by engineers who have decades of hands-on experience designing and shipping at Bay Area, California startups and big tech with hardware, software, integration, manufacturing, and supply chain expertise across critical components and systems for autonomy, unmanned systems and robotics in all domains.

FAQ

Q: What about X component?

A: Yes, we’re intersted to learn more. Let’s discuss.

| Text or Email your requirements. Get started now. |

| + 1415 812 3326 | info@substep.xyz | Substep LLC |

|---|---|---|

|